CUSTOM STORAGE OF (LIQUEFIED) GASES

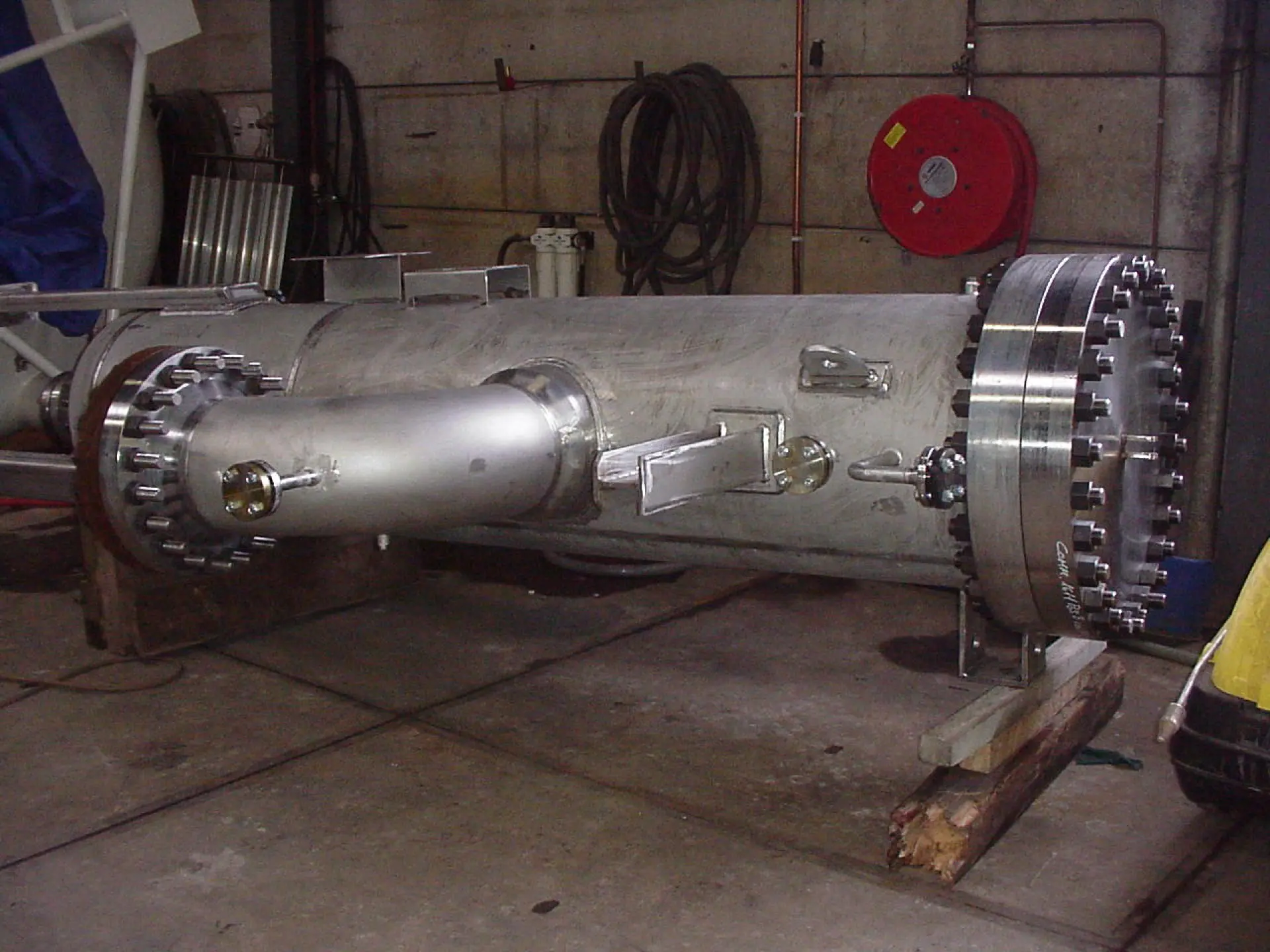

Tankbouw Rootselaar manufactures stationary pressure vessels to store (liquefied) gas or use them as process vessels for contractors and gas companies.

We produce single tanks and small series. Furthermore, the vessels are customised to meet your demands. So when you need a vessel whose size, volume, piping, or other features are out of the ordinary, we are your go-to partner.

Our pressure vessels are made of stainless, duplex or carbon steel. In terms of their contents, they can hold propane/butane (LPG), liquefied carbon dioxide (LCO₂), carbon dioxide (CO₂), hydrogen (H2), nitrous oxide (N2O), ammonia (NH3), freons, dimethyl ether (DME), (compressed) air, and steam/hot water.

Some specifications:

These vessels are single-walled and foam insulated. Alternatively, Rootselaar Group member Cryovat International produces vacuum insulated containers. Visit Cryovat International for more information about cryogenic equipment.

We don’t build our tanks from scratch. Instead, we use standard vessels or previous designs and tailor them to meet specific demands. This practice illustrates the pragmatic mindset we harness to meet often complex customer requirements. We call this: customing international standards.

Tankbouw Rootselaar is ISO 9001-certified. In addition, our equipment is produced in compliance with many other international certifications and design codes, including ASME-U/U2 and CE-marking/PED. Furthermore, we are well-versed in the Dutch Publication Series on Hazardous Substances (PGS).

Inspections are carried out by authorised agencies - third parties can be involved if required. Furthermore, we are certified by Dutch Authorities to design and install propane, butane and LPG installations.

Read more about our Quality Assurance system.

Tankbouw Rootselaar has a highly skilled engineering team. They use specialised calculation software and 3D CAD programmes to provide most designs for our pressure vessels.

Read more about our engineering expertise.

Should you require a design beyond tank manufacturing, we engage Hadetec. This engineering company, and fellow Rootselaar Group member, can add additional features, device skid-mounted packages and provide designs not based on standard products.

Would you like to learn more about our custom-built foam insulated pressure vessels? We welcome you to contact us.

Do you have a question about our products or services? Feel free to contact us at any time. We would love to hear from you!